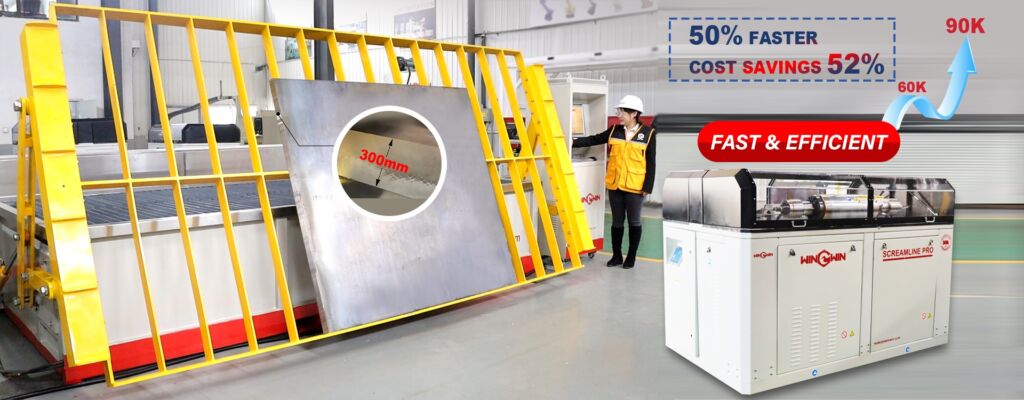

Waterjet Cutting Machine The water at atmospheric pressure (0.2MPa) passes through a booster pump, pressurized to 350Mpa or higher, blows out through a small hole, mixes the sand, and uses high-speed sand to cut. No thermal deformation, no burr, and no need for secondary processing.

Can cutting shape a variety of complex patterns, is a cold cutting, and will not produce thermal deformation or thermal effect.are some composite materials, the only means of complex processing of fragile porcelain materials; can complete drilling, cutting, molding work at one time; low production cost; high degree of automation; can work continuously for 24 hours.

The punching and shearing process method can be adopted for some metal machines with high effectiveness and high speed, but specific molds and cutting tools are necessary. Water cutting is more flexible than this cutting method,

And the cutting of randomly shaped workpieces can be stopped at any time. the thickness scale of flame cutting is unusually large, but compared with water cutting, it has a significant thermal effect, poor external quality, and precision. Other water cutting can well handle the cutting of some special data, such as high melting point, alloy, composite data, and so on.

Is it necessary to have a firm fixture for waterjet cutting? From the point of view of mechanics, in the process of waterjet cutting, the material is only subjected to the vertical upward force, and the degree of the force is extremely small, just like there is no need for a large firm fixture, and the lighter data need to be pressed by heavy objects when cutting to prevent the attack of recoil water from affecting the processing

accuracy.

Benefits of waterjet cutting:

- Low music to 75dB is as follows.

- 2. Reduce the signs of frost on the outside of the material.

Insufficient waterjet cutting

- Helplessly monitor the cutting process.

- If you have no choice but to stop material processing,

it is necessary to set up equipment and an adjustable water-level desk.

How long can the waterjet nozzle (abrasive tube) be used continuously?

The factors affecting the application of abrasive tubes are the difference in abrasive, the difference in assembly accuracy, the difference in application method, the influence of gem nozzle, and the influence of sand pipe itself. As usual, hours. Is it necessary to punch holes after waterjet cutting?

Water waterjet cutting is not necessary to punch holes afterward, in cutting, the water jet will take the initiative to penetrate the material and then stop cutting. Is it difficult to program waterjet cutting?

Water waterjet cutting machine for the CNC numerical control system, the French style absolutely other cutting skills are not difficult.