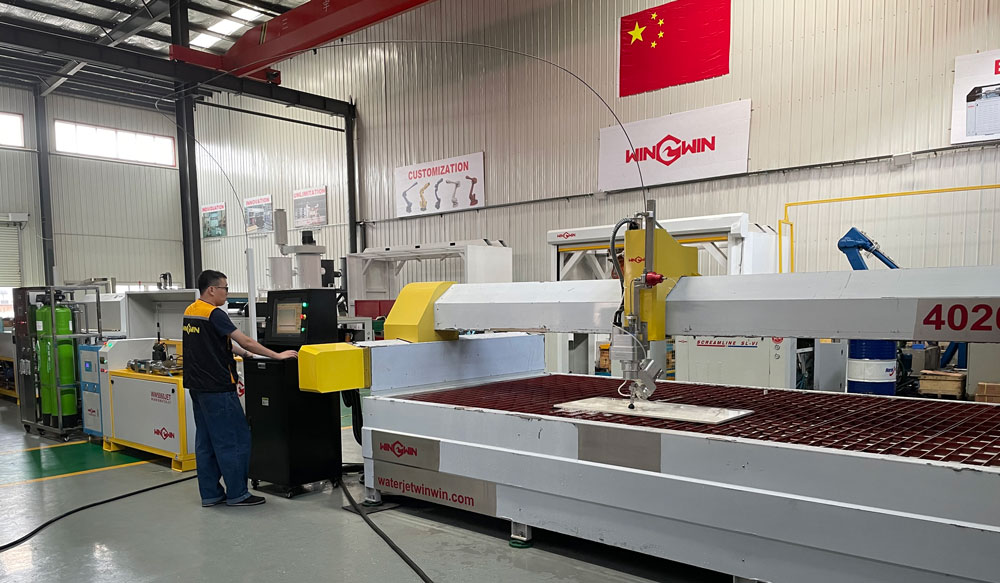

WINWIN peut vous fournir une machine de découpe au jet d'eau robotisée complète, qui peut être personnalisé selon vos besoins. Nos clients viennent du monde entier. Ce client nous a acheté une autre machine de découpe au jet d'eau robotisée.

They have purchased 9 sets of robot cells from us, have 5 production lines. Due To the increase in business volume, they purchased a new production line for cutting automotive interiors multi layer materials cutting last month.

According to our customer’s demand for production of automotive interior products, WINWIN was entrusted to design and manufacture a robot waterjet cutting system, using two FANUC 710IC robotic arms with stationary double stations,which can cut two materials at the same time.

Ce système de découpe au jet d'eau robotisé se compose d'un système de contrôle général, pompe à haute pression, système d'adsorption sous vide, grand système de refroidissement industriel, système de filtration d'eau, barrière de sécurité.

| Type de robot | Bras robotiques Fanuc 710IC avec système de contrôle |

| Table de découpe | Table rotative en acier inoxydable |

| Pompe d'intensification | Pompe hydraulique haute pression |

| Système de refroidissement | 5Refroidisseur industriel grande capacité HP |

| Système d'adoucissement de l'eau | RO. Système avec une capacité d'adoucissement de 1,5 T/heure |

| Système d'adsorption | 9.6 Ventilateur d'adsorption à pression négative RPM |

What’s the feature of this robot arm?

WINWIN can not only provide the robot waterjet cutting machine, but also customize the design of the high pressure pipe lines for the robot arm.Our professional technicians design special high pressure pipe lines according to the model of each robot, which can prolong the service life of the robot.

Many customers have reported that the high pressure pipes lines they bought before are easy to break. WINWIN’s high pressure pipes have screened a number of material suppliers. We will let the high pressure pipe work continuously for three months, 24 hours a day, so as to monitor the use of the high pressure pipe.

Maintenant, we have a large number of high quality robot waterjet cutting high pressure pipes in stock. The high pressure pipes in our inventory are of the best quality. Because our inventory is huge, our prices are also very favorable, even more favorable than manufacturers.The high-pressure pipes we produce can be used for continuous work under 90,000 psi ultra high pressure, and according to customer needs we can do customized design of length and shape.

What brand is this safety curtain?

The materials and brands we use for our customers are all high-quality brands,this uses Omron’s safety light curtain, which can protect the staff and has a high safety factor,create a safe work environment.

What is the difference between the 90,000 psi waterjet high pressure pump and others

La première est la différence de matériau de coupe et d'épaisseur. La machine de découpe au jet d'eau robot et la pompe peuvent couper l'acier inoxydable, aluminium, cuivre, acier, marbre, alliage métallique, verre, Plastique, céramique, carrelages et divers matériaux apparents.

Des matériaux métalliques aux matériaux non métalliques, des matériaux naturels aux matériaux artificiels, de la nourriture aux nécessités quotidiennes, même les troupes peuvent utiliser des jets d'eau pour démanteler certaines bombes. Mais si vous avez besoin de couper un intérieur automobile multicouche ou un métal ultra-épais de 300 millimètre, 90000 La pompe intensificateur à jet d'eau psi est votre meilleur choix.

As the first robot waterjet cutting supplier that breaks through the ultra-high pressure technology in China,Winwin’s 90000 psi intensifier pump has been officially put into production.

From 3.8 L/min ordinary flow rate to 7.8 L/min 100 hp large flow rate, cutting pressure from 60000 psi to 90000 psi, not only realizes 6 manipulators in one drive, but also realizes the cutting of ultra-thick and super-hard multi layer automotive interior materials.

ow to control the whole robot system?

As you can see, il existe deux ensembles de systèmes de contrôle. Ce système de contrôle est livré avec le robot FUNUC lui-même. Ce système de contrôle est conçu par GAGNANT techniciens spécifiques. Et nous équipons le robot d'une configuration haut de gamme, refroidisseur de qualité industrielle, système de filtration d'eau professionnel, et système d'adsorption sous vide spécifique au robot.

En tant qu'agent désigné de fanuc, ABB, yaskawa, et kuka en Chine, winwin peut fournir à ses clients tout type de système de découpe robotisé.

Si vous avez également besoin de couper des intérieurs de voiture, WINWIN peut vous fournir le système de robot le plus professionnel.

La qualité et le délai de livraison ont toujours été les principaux éléments de garantie de WINWIN, si vous êtes également intéressé par la découpe robotisée au jet d'eau, Bienvenue à me contacter.

2.Est-il possible d'acheter des têtes de coupe et des systèmes d'exploitation dans la société WINWIN waterjet?

Un client des Emirats Arabes Unis a consulté WINWIN au sujet de la tête de découpe robotisée au jet d'eau et du logiciel de contrôle de la machine de découpe à l'eau. He has his own cutting table and wants to buy cutting head and system for marble and ceramic tile processing factory machine ,a set of five axis waterjet cutting machine.

But they have difficulties on the cutting head and control software. Now it is necessary to purchase a five-axis cutting head and some motors to complete the system and change it into a Weihong system. We have provided cutting solutions for the customer.

D'abord, the first set of solutions, we provide customers with 3 solutions, this is one of them, les composants équipés sont: système de contrôle et son armoire; Moteur axe X, fils connexes, conducteur; Moteur axe Y, fils connexes, conducteur ; Moteur axe Z, fils connexes, conducteur; Moteur axe A, fils connexes, conducteur; Moteur axe C, fils connexes, conducteur; Tête de coupe AC.

Et deux autres solutions, les clients intéressés peuvent nous contacter pour des solutions.

À la fin, le client a choisi la première solution et a payé les produits, parce que nous aiderons le client à installer et à déboguer toute la tête de coupe et le système avant que le client ne récupère les produits. Après que le client ait reçu le système de coupe,

il peut l'utiliser directement sans l'assembler lui-même. Nous avons organisé la livraison pour le client hier, le poids total est de 250KG.

Si vous avez également besoin d'assembler vous-même un équipement de coupe AC 5 axes, veuillez nous contacter. De nombreux clients veulent savoir comment utiliser la tête de coupe et le système,Le logiciel à jet d'eau à cinq axes prend en charge les formats de code DXF et G,

Le premier pas, utiliser d'autres ordinateurs pour tracer le graphique (DXF 、format), la deuxième étape, importer le dessin dans le système, le système affiche directement les graphiques, and then our client can do cutting work.

WINWIN can not only provide you with various technical and components support for assembling robot waterjet cutting machines, but also provide you with a complete set of robot waterjet cutting machines.Welcome to contact us to solve your machine needs.

3.Abrasive waterjet cutting machine

Another abrasive waterjet cutting machine of WINWIN has completed the design, production, assembly, and now the machine is on testing and customer trial cutting before leaving factory.This equipment is AC five axis Abrasive waterjet cutting machine with 40 motor power intensifier pump.

Compared with the gantry structure machine, this machine has two advantages.

First is the cantilever structure,can complete the cutting of any complex plane curve. Users can load and unload parts from three directions, overcoming the shortcomings of narrow loading and unloading space of gantry machine.

Deuxièmement,the size of this machine is 4m*2m, et il ne peut être chargé que dans un conteneur de 40 pieds pour le transport. Après avoir adopté la structure en porte-à-faux, l'ensemble des machines peut être chargé dans un conteneur de 20 pieds, ce qui permet d'économiser les frais de transport pour les clients.

Outre la table de découpe,nous équipons le système de coupe avec une pompe intensificateur haute configuration.420MPA,Grand refroidisseur industriel,Système de contrôle général CNC,système d'alimentation en abrasif automobile.

Cette table de coupe adopte une structure de portique entièrement protectrice en acier inoxydable et immergée dans l'huile ,can prolong the service life of lead screw slider.

This is AC 5 axis cutting head , its max swing angle can reach sixty-eight degrees and widely used in marble cutting industry.

This is a brief introduction, welcome all of you to contact me for more details , thank you.

If you need high-end water cutting system, Contactez nous s'il vous plait, we will become your reliable partner.

4.About working voltage

Customer request: I want to buy a high-quality waterjet cutting machine to install in Mexico factory, the required voltage is 440 V, can we use the machine with 440 V voltage?

We answered: Oui, you can use 440 V voltage to run the water cutting machine, we will debug it before delivery, and we can go to your factory for installation.

5.Can you customize high pressure pumps? We need a 20HP high-pressure pump for cleaning laboratory equipment. What is the difference between you and others?

Bien sûr, we are a company that specializes in providing customized equipment and waterjet cutting parts for customers. The general pumps on the market are standard 40 or 50HP, and 20HP low-pressure customization is rarely produced by companies.

D'abord, if you want to change to a small power, it is not just a simple replacement of a motor, we need to change the frame, link, structure.All needs engineer’s experience and continuous debugging, this is not easy.

Deuxièmement, we have experience in making low-pressure customized pumps. We have produced such equipment for a food processing factory in the United States, and we have rich experience and mature technology.

1.Do you have pipe bending and threading tools? Is it necessary to buy the whole set?

Oui, we have a complete set of bending, threading and coning tools, including 1/4″, 3/8″, 9/16″ high pressure pipe thread and coning tools, and can be used for 1/4″ et 3 /8″ high pressure pipe for bending.

With this set of tools, you can easily deal with water leakage and bursting of high-pressure pipes. It only takes a few minutes to process and replace them, without delaying production at all, so it is recommended that you buy them all.

2.I want to buy high end waterjet spare parts from you, what are the advantages of your company?

1. winwin can provide you with this service, we have an agent in many countries and can contact you. Our professional after-sales service team has rich maintenance experience to solve problems for customers.

2. The related partses of I50 high pressure pump produced by WinWin factory are high-quality parts that have been inspected by customers. They are all in stock in the warehouse and will be shipped immediately after payment. Our 50HP, 60HP, 100HP, 60000psi, 90000psi series waterjet intensifier pumps have been sold to dozens of countries in the world.

Our customers use them for the production of automotive interior waterjet cutting, marbre, ultra thick metal cutting, etc. Especially the 90000PSI ultra high pressure pump is the first waterjet cutting factory in China to put UHP ultra high pressure pump into production.

3. WinWin waterjet company is an ODM factory specializing in the production of waterjet cutting spare parts and machines. We have a professional technical team to provide you with technical support at any time.

The factory has a complete range of products: there are robotic water jet cutting systems, various series of high pressure pumps, abrasive waterjet cutting machines, and abrasive waterjet cutting spare parts, so we can provide you with a full range of products required for maintenance.

4. The robot waterjet cutting solution of winwin factory mainly serves global automotive interior processing factories. And we have maintained long-term cooperative relationship with ABB, YASKAWA, FUNAC robots. en outre,

we have won dozens of patent certificates, including CE certification of machines, etc., to provide you with reliable technical guarantee.

5. We have been exporting waterjet cutting machines and waterjet spare parts to all over the world for a long time, so we have prepared a variety of payment methods for our customers, and the payment is quick. Logistics has DHL, FEDEX, aliexpress, special line and other logistics methods, and has become a VIP customer of these methods.

6. The winwin factory has full-time staff to communicate with different language customers, and uses them as the communication language, making communication barrier free and convenient for customers.

3.If I buy the abrasive feeder tank from you, can you provide me the manual?

Oui, firstly we need to confirm with you whether you have one air pipe or two air pipes, we have different abrasive feeder tank.

In addition to the manual, we have a video on how to connect and install the abrasive feeder tank. The manual shows the part name, purpose and connection method of each part of the abrasive feeder tank.

If you have any problems during the connection process, we will solve it for you at any time.

We have great after sales service,parce que nous sommes la vente directe d'usine, return and refund guaranteed. You can ask any questions about our products through our 24 / 7 online service, où vous recevrez des réponses rapides et professionnelles.