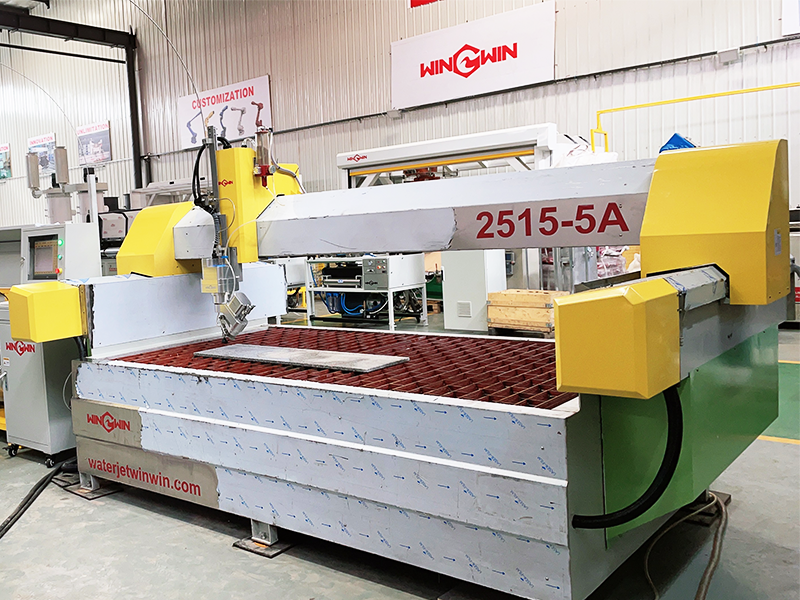

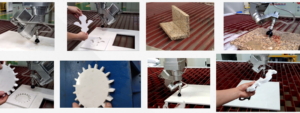

2015AC5A waterjet cutting machine is suitable for cutting rock plate. Machine tool length 2000mm, width 3100mm, weight 2560kg. AC 5-axis cutting head: infinite rotation, laser height measurement, automatically drying water, surface automatic cutting, cutting section angle ±68°. Products can be processed: rock plate basin, table facet, kitchen island, dining table, end table, and a variety of irregular patterns.

The AC 5-axis waterjet cutting machine of gantry structure consists of the following seven units:

- 2015 Cutting Table

- Waterjet Cutting Intensifier Pump WW5060

- Waterjet Cutting Control System

- Automatic Abrasive Feeder Tank

- Cooling System

- Water FiltrationSystem

- Automatic Abrasive Removal System

Part I: 2015AC5A Waterjet Cutting Table

| Series | CA 2515 jato de água | Tipo | Pórtico |

| Cabeça de corte | CA 5 eixo | Precisão de controle | ±0,01mm |

| Ângulo de corte | 0-±68° | Curso do eixo Z | 200milímetros |

| Precisão de corte | ±0,1 mm | Precisão de reposicionamento | ±0,05mm |

| Velocidade de corte | 11000mm/min | Motor | 30quilowatts/40HP |

| Máx.. faixa de corte | 2500mmx1500mmx200mm | Certificado | CE/ISO |

- Estrutura imersa em óleo, parafuso de avanço e corrediça imersos em óleo lubrificante que estão totalmente lubrificados, maior tempo de uso, maior precisão

- A tampa protetora de aço inoxidável totalmente fechada evita efetivamente que abrasivos e água entrem na pista de corrida e protege a vida útil do parafuso de avanço e do controle deslizante

- Projeto de limite duplo, evitando que máquinas-ferramentas colidam devido a operação incorreta, o fator de segurança das máquinas-ferramentas é melhorado

- O parafuso de avanço grosso e o controle deslizante grande podem fazer a máquina-ferramenta funcionar em alta velocidade sem tremulação

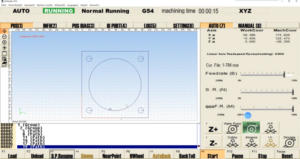

- O sistema de controle, servo motor, driver and signal line all use the brand of WEIHONG, which enhances the overall compatibility and makes the machine more stable

- Use flexible towing chain, preventing aging, prevent freezing and cracking; fireproof material, ensuring the long use of towing chain

- The water tank uses 5mm thick steel to ensure the overall strength of the frame

- Double Y structure, adjustable precision, not subject to geographical restrictions, can be installed in any environment

- Manual adjustment of abrasive feeder tank, stable work, no failure

- Standard AC 5-axis cutting head for indefinite rotation

Standard models of cutting table are: 2015, 3015, 3020, 4020, etc. Other sizes can be customized.

Part II: Waterjet Cutting Intensifier Pump WW5060 PUMP

Types of waterjet cutting intensifier pump: 90,000PSI PUMP, SL-VI 100HP PUMP, SL-VI50JP PUMP, WW60JET PUMP, JET50 PUMP, WW40JET PUMP, WW5060JET PUMP. The choice of intensifier pump is based on the cutting material and application. You can consult us for more information, we will give you better advice.

| Brand | WIN-WIN | Modelo | WW5060JET |

| Attenuator capacity | 1L | Driving mode | High performance motor |

| Voltage | 380V/others | Inscrição | Water jet cutting system |

| Rated power | 40HP | Maximum water flow | 3.8L/min |

| Pressão no trabalho | 420Mpa | Continuous working pressure | 320Mpa-380Mpa |

| Driving orifices Qty. | 1-2 | Temperatura | 5-40°C |

| Hydraulic oil type | No.46 anti-wear oil | Cooling method | Cool-heat exchange |

| Tamanho (L * w * h) | 1.2m*1.1m*1.4m | Weight | 0.8T |

WW5060 waterjet cutting intensifier pump is a basic type of intensifier pump, and its market penetration is strong. It was actually produced in 1990 and has been used steadily ever since. It is widely used in metal cutting, stone cutting, glass cutting, rubber cutting and other industries, which is a basic universal waterjet cutting intensifier pump. This intensifier pump has a full protection structure with all metal protection, applicable to any conditions and site. Many customers directly choose this basic intensifier pump.

- International universal supercharger core, can be purchased in the local and any waterjet cutting accessories mall, the universality is very strong

- Full metal protection structure, suitable for various working conditions

- Reasonable design is conducive to fast maintenance and easy operation

- All water joints are made of stainless steel to prevent rust

- The core parts of the supercharger are imported from the United States to ensure durability

- Omron PLC, Schneider Electric, uses big brands of appliances to ensure circuit stability

- Japanese brand reversing valve, so that the machine reversing without delay, small sound, stable pressure

- Independent variable pump, to zero pressure waiting, low pressure start, high pressure operation, more energy saving

- Brand motor, can be used is used, not broken at present, motor with overload protection function

- Stainless steel secondary intensifier pump to prevent internal rust from causing damage to the high-pressure accessories of the intensifier pump

- Transparent triple water filter element, easy to observe the state of the filter element and replace in time

- Use imported high pressure pipe, can be used for more than one year

- Normal working pressure 50000psi, stable working, low failure rate

- Copper cooling device, good cooling effect, hydraulic seal protection

- Noise less than 70 decibels, to create a good environment for the factory

- Servo motor/stepper motor is optional

- Equipped with 1L accumulator to ensure the stability of cutting pressure

- Strong welded steel pipe frame, machine operation will not tremble

- Transparent cover design allows you to observe core dynamics at any time

- Automatic pressure relief function, the entire machine has automatic stop protection system

Part V: Waterjet Cutting Cooling System

As you know, the pump is driven by hydraulic oil for

intensifier work. Excessive hydraulic oil temperature

will seriously affect the service life of the metal parts

and sealing parts of the hydraulic part in the intensifi-

er pump.

Refrigerator Cooling with super cooling effect, internal

closed circulation system, more environmental health,

beautiful appearance, reliable performance.

This refrigerator is different from the refrigerators on the market. This refrigerator is the product produced by the manufacturer according to the technical requirements of WINWIN. The internal structure has been changed to make it more suitable for the temperature of the cooling waterjet cutting intensifier pump.

Part VI: Waterjet Cutting Water Filtration System

A certain amount of scale will be generated during the

use of waterjet cutting, and the scale will easily cause

the parts to wear, thereby increasing the failure rate.

This system can filter out particles, impurezas, etc. in

the water, and effectively remove calcium and magne-

sium ions in the water to prevent scale formation, thus

protecting the machine and prolonging the life of ma-

chine parts.

- Use a water filtration system to remove calcium and magnesium ions from water to prevent scaling.

- Good water quality will not only increase the life of the seal but also prolong the reliability and life of the nozzle, orifice,

- high pressure seal etc. resulting in more efficient cutting.

Part VII: Water Cutting Automatic Abrasive Removal System

After the waterjet has been used for a long time,

waste abrasive will accumulate in the water

sink. When it reaches a certain level, we need to

do the work of cleaning the waste abrasive, in

the traditional abrasive removal, we have to stop

the work of the cutting table and do manual

abrasive removal.

Agora, with the mobile abrasive removal system,

we can remove abrasive without affecting nor-

mal cutting, and it is an automatic abrasive re-

moval system.

- Optional Devices Abrasive Removal System

- When the waterjet cutting machine operates, the large-scale abrasive removal system operates automatically without affecting each other.

- The device can be installed within 10m of the waterjet cutting machine.

- The flow rate can reach 162L/min.

- The abrasive removal rate is more than 90%.

- During the entire abrasive removal process, the filtered water continues to be discharged into the water sink, and the water sink does not need to be replenished after abrasive removal.

Resumo: The above describes all units of a set of waterjet cutting machine, among which cooling system, water filtration system, abrasive removal system are optional units. É claro, customers can also choose to buy locally, but it is recommended that customers choose to buy this unique cooling system. Here attached to you is the list of the complete set of waterjet cutting machine.