WINWIN can provide you with a complete robot waterjet cutting machine, which can be customized according to your needs. Our customers come from all over the world. This customer purchased another robot waterjet cutting machine from us.

They have purchased 9 sets of robot cells from us, have 5 production lines. Due To the increase in business volume, they purchased a new production line for cutting automotive interiors multi layer materials cutting last month.

According to our customer’s demand for production of automotive interior products, WINWIN was entrusted to design and manufacture a robot waterjet cutting system, using two FANUC 710IC robotic arms with stationary double stations,which can cut two materials at the same time.

This robot waterjet cutting system consists of general control system, high pressure pump, vacuum adsorption system, industrial grand cooling system, water filtration system, security barrier.

| Robot Type | Fanuc 710IC Robot Arms with Control System |

| Cutting Table | Stainless Steel Table Rotary Table |

| Intensifier Pump | Hydraulic High Pressure Pump |

| Cooling System | 5HP Large Capacity Industrial Chiller |

| Water Softening System | R.O. System with 1.5T/hour Softening Capacity |

| Adsorption System | 9.6 RPM Negative Pressure Adsorption Fan |

What’s the feature of this robot arm?

WINWIN can not only provide the robot waterjet cutting machine, but also customize the design of the high pressure pipe lines for the robot arm.Our professional technicians design special high pressure pipe lines according to the model of each robot, which can prolong the service life of the robot.

Many customers have reported that the high pressure pipes lines they bought before are easy to break. WINWIN’s high pressure pipes have screened a number of material suppliers. We will let the high pressure pipe work continuously for three months, 24 hours a day, so as to monitor the use of the high pressure pipe.

At present, we have a large number of high quality robot waterjet cutting high pressure pipes in stock. The high pressure pipes in our inventory are of the best quality. Because our inventory is huge, our prices are also very favorable, even more favorable than manufacturers.The high-pressure pipes we produce can be used for continuous work under 90,000 psi ultra high pressure, and according to customer needs we can do customized design of length and shape.

What brand is this safety curtain?

The materials and brands we use for our customers are all high-quality brands,this uses Omron’s safety light curtain, which can protect the staff and has a high safety factor,create a safe work environment.

What is the difference between the 90,000 psi waterjet high pressure pump and others

The first is the difference in cutting material and thickness.robot Waterjet cutting machine and pump can cut stainless steel, aluminum, copper, steel, marble, alloy metal, glass, plastic, ceramics, tiles and various visible materials.

From metal materials to non metal materials, from natural materials to artificial materials, from food to daily necessities, even troops can use water jets to dismantle some bombs.But if you need to cut multi-layer automotive interior or ultra-thick metal of 300 mm, 90000 psi waterjet intensifier pump is your best choice.

As the first robot waterjet cutting supplier that breaks through the ultra-high pressure technology in China,Winwin’s 90000 psi intensifier pump has been officially put into production.

From 3.8 L/min ordinary flow rate to 7.8 L/min 100 hp large flow rate, cutting pressure from 60000 psi to 90000 psi, not only realizes 6 manipulators in one drive, but also realizes the cutting of ultra-thick and super-hard multi layer automotive interior materials.

ow to control the whole robot system?

As you can see, there are two sets of control systems. This control system comes with FUNUC robot itself. This control system is designed by WINWIN specific technicians.And We equip the robot with high-end configuration, industrial-grade chiller, professional water filtration system, and robot-specific vacuum adsorption system.

As the designated agent of fanuc, ABB, yaskawa, and kuka in China, winwin can provide customers with any type of robot cutting system.

If you also need to cut car interiors, WINWIN can provide you with the most professional robot system.

Quality and delivery time have always been the primary guarantee elements of WINWIN, if you are also interested in robot waterjet cutting, welcome to contact me.

2.Is it possible to buy cutting heads and operating systems in WINWIN waterjet company?

A customer from the United Arab Emirates consulted WINWIN about the robot waterjet cutting head and control software of the water cutting machine. He has his own cutting table and wants to buy cutting head and system for marble and ceramic tile processing factory machine ,a set of five axis waterjet cutting machine.

But they have difficulties on the cutting head and control software. Now it is necessary to purchase a five-axis cutting head and some motors to complete the system and change it into a Weihong system. We have provided cutting solutions for the customer.

First of all, the first set of solutions, we provide customers with 3 solutions, this is one of them, the equipped components are: control system and its cabinet; X-axis motor, related wires, driver; Y-axis motor, related wires, driver ; Z-axis motor, related wires, driver; A-axis motor, related wires, driver; C-axis motor, related wires, driver; AC cutting head.

And other two solutions, interested customers can contact us for solutions.

In the end, the customer chose the first solution and paid for the products, because we will help the customer to install and debug all the cutting head and system before the customer picks up the products. After the customer gets the cutting system,

he can use it directly without assembling it by himself.We arranged the delivery for the customer yesterday, the overall weight is 250KG.

If you also have the need to assemble AC 5 axis cutting equipment by yourself, please contact us.Many clients want to know how to use the cutting head and system,five axis waterjet software support DXF and G code format,

The first step, using other computers to draw the graph (DXF 、format), the second step, import the drawing into the system, the system directly display graphics, and then our client can do cutting work.

WINWIN can not only provide you with various technical and components support for assembling robot waterjet cutting machines, but also provide you with a complete set of robot waterjet cutting machines.Welcome to contact us to solve your machine needs.

3.Abrasive waterjet cutting machine

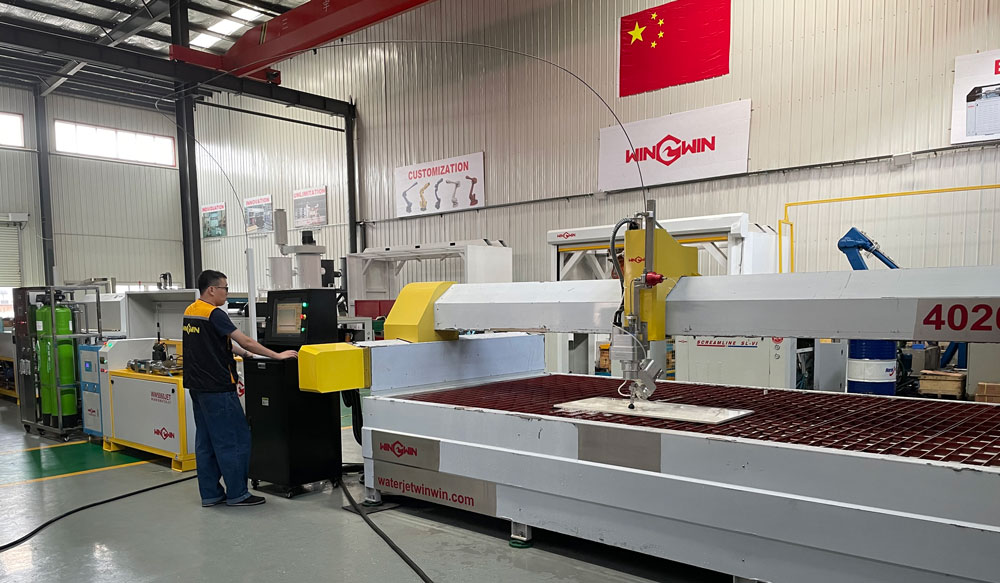

Another abrasive waterjet cutting machine of WINWIN has completed the design, production, assembly, and now the machine is on testing and customer trial cutting before leaving factory.This equipment is AC five axis Abrasive waterjet cutting machine with 40 motor power intensifier pump.

Compared with the gantry structure machine, this machine has two advantages.

First is the cantilever structure,can complete the cutting of any complex plane curve. Users can load and unload parts from three directions, overcoming the shortcomings of narrow loading and unloading space of gantry machine.

Secondly,the size of this machine is 4m*2m, and it can only be loaded into a 40-foot container for transportation. After adopting the cantilever structure, the whole set of machines can be loaded into a 20-foot container, which saves transportation costs for customers.

Besides the cutting table,we equip the cutting system with high configuration.420MPA intensifier pump,Industrial grand chiller,CNC general control system,automotive abrasive supply system.

This cutting table adopts full protective stainless steal and oil-immersed gantry structure ,can prolong the service life of lead screw slider.

This is AC 5 axis cutting head , its max swing angle can reach sixty-eight degrees and widely used in marble cutting industry.

This is a brief introduction, welcome all of you to contact me for more details , thank you.

If you need high-end water cutting system, please contact us, we will become your reliable partner.

4.About working voltage

Customer request: I want to buy a high-quality waterjet cutting machine to install in Mexico factory, the required voltage is 440 V, can we use the machine with 440 V voltage?

We answered: Yes, you can use 440 V voltage to run the water cutting machine, we will debug it before delivery, and we can go to your factory for installation.

5.Can you customize high pressure pumps? We need a 20HP high-pressure pump for cleaning laboratory equipment. What is the difference between you and others?

Of course, we are a company that specializes in providing customized equipment and waterjet cutting parts for customers. The general pumps on the market are standard 40 or 50HP, and 20HP low-pressure customization is rarely produced by companies.

First of all, if you want to change to a small power, it is not just a simple replacement of a motor, we need to change the frame, link, structure.All needs engineer’s experience and continuous debugging, this is not easy.

Secondly, we have experience in making low-pressure customized pumps. We have produced such equipment for a food processing factory in the United States, and we have rich experience and mature technology.

1.Do you have pipe bending and threading tools? Is it necessary to buy the whole set?

Yes, we have a complete set of bending, threading and coning tools, including 1/4″, 3/8″, 9/16″ high pressure pipe thread and coning tools, and can be used for 1/4″ and 3 /8″ high pressure pipe for bending.

With this set of tools, you can easily deal with water leakage and bursting of high-pressure pipes. It only takes a few minutes to process and replace them, without delaying production at all, so it is recommended that you buy them all.

2.I want to buy high end waterjet spare parts from you, what are the advantages of your company?

1. winwin can provide you with this service, we have an agent in many countries and can contact you. Our professional after-sales service team has rich maintenance experience to solve problems for customers.

2. The related partses of I50 high pressure pump produced by WinWin factory are high-quality parts that have been inspected by customers. They are all in stock in the warehouse and will be shipped immediately after payment. Our 50HP, 60HP, 100HP, 60000psi, 90000psi series waterjet intensifier pumps have been sold to dozens of countries in the world.

Our customers use them for the production of automotive interior waterjet cutting, marble, ultra thick metal cutting, etc. Especially the 90000PSI ultra high pressure pump is the first waterjet cutting factory in China to put UHP ultra high pressure pump into production.

3. WinWin waterjet company is an ODM factory specializing in the production of waterjet cutting spare parts and machines. We have a professional technical team to provide you with technical support at any time.

The factory has a complete range of products: there are robotic water jet cutting systems, various series of high pressure pumps, abrasive waterjet cutting machines, and abrasive waterjet cutting spare parts, so we can provide you with a full range of products required for maintenance.

4. The robot waterjet cutting solution of winwin factory mainly serves global automotive interior processing factories. And we have maintained long-term cooperative relationship with ABB, YASKAWA, FUNAC robots. In addition,

we have won dozens of patent certificates, including CE certification of machines, etc., to provide you with reliable technical guarantee.

5. We have been exporting waterjet cutting machines and waterjet spare parts to all over the world for a long time, so we have prepared a variety of payment methods for our customers, and the payment is quick. Logistics has DHL, FEDEX, aliexpress, special line and other logistics methods, and has become a VIP customer of these methods.

6. The winwin factory has full-time staff to communicate with different language customers, and uses them as the communication language, making communication barrier free and convenient for customers.

3.If I buy the abrasive feeder tank from you, can you provide me the manual?

Yes, firstly we need to confirm with you whether you have one air pipe or two air pipes, we have different abrasive feeder tank.

In addition to the manual, we have a video on how to connect and install the abrasive feeder tank. The manual shows the part name, purpose and connection method of each part of the abrasive feeder tank.

If you have any problems during the connection process, we will solve it for you at any time.

We have great after sales service,because we are factory direct sale, return and refund guaranteed. You can ask any questions about our products through our 24 / 7 online service, where you will receive timely and professional answers.