Part V: Waterjet Cutting Cooling System

As you know, the pump is driven by hydraulic oil for

intensifier work. Excessive hydraulic oil temperature

will seriously affect the service life of the metal parts

and sealing parts of the hydraulic part in the intensifi-

er pump.

Refrigerator Cooling with super cooling effect, internal

closed circulation system, more environmental health,

beautiful appearance, reliable performance.

This refrigerator is different from the refrigerators on the market. This refrigerator is the product produced by the manufacturer according to the technical requirements of WINWIN. The internal structure has been changed to make it more suitable for the temperature of the cooling waterjet cutting intensifier pump.

Part VI: Waterjet Cutting Water Filtration System

A certain amount of scale will be generated during the

use of waterjet cutting, and the scale will easily cause

the parts to wear, thereby increasing the failure rate.

This system can filter out particles, impurities, etc. in

the water, and effectively remove calcium and magne-

sium ions in the water to prevent scale formation, thus

protecting the machine and prolonging the life of ma-

chine parts.

- Use a water filtration system to remove calcium and magnesium ions from water to prevent scaling.

- Good water quality will not only increase the life of the seal but also prolong the reliability and life of the nozzle, orifice,

- high pressure seal etc. resulting in more efficient cutting.

Part VII: Water Cutting Automatic Abrasive Removal System

After the waterjet has been used for a long time,

waste abrasive will accumulate in the water

sink. When it reaches a certain level, we need to

do the work of cleaning the waste abrasive, in

the traditional abrasive removal, we have to stop

the work of the cutting table and do manual

abrasive removal.

Now, with the mobile abrasive removal system,

we can remove abrasive without affecting nor-

mal cutting, and it is an automatic abrasive re-

moval system.

- Optional Devices Abrasive Removal System

- When the waterjet cutting machine operates, the large-scale abrasive removal system operates automatically without affecting each other.

- The device can be installed within 10m of the waterjet cutting machine.

- The flow rate can reach 162L/min.

- The abrasive removal rate is more than 90%.

- During the entire abrasive removal process, the filtered water continues to be discharged into the water sink, and the water sink does not need to be replenished after abrasive removal.

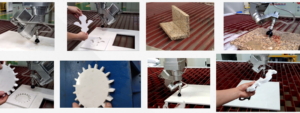

Summary: The above describes all units of a set of waterjet cutting machine, among which cooling system, water filtration system, abrasive removal system are optional units. Of course, customers can also choose to buy locally, but it is recommended that customers choose to buy this unique cooling system. Here attached to you is the list of the complete set of waterjet cutting machine.

| Item | Item Name | Description | Quantity |

| 1 | Cutting Table | 4000mmx2000mm Cutting Area Gantry Type | 1 |

| 2 | High Pressure Pump | WW50JET Pump 50HP 60,000 Psi | 1 |

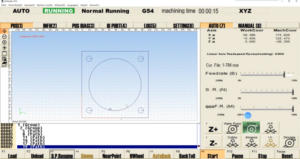

| 3 | Cabinet CNC system | WEIHONG® WATERJET Control System | 1 |

| 4 | Automatic abrasive supply system | 200Kg Pneumatic Auto Feeder Tank | 1 |

| 5 | cooling system | tailor-made style cooling system | |

| 6 | Water softening and purification | R.O. Water softening filtration system | 1 |

| 7 | Sludge treatment system | Automatically remove the precipitated abra- sive in the cutting table | 1 |